Mass Timber Innovation: All-Wood

Mass Timber Innovation: All-Wood

If contemporary discussion around mass timber has gravitated towards the possibility of “Tall-Wood” buildings, our body of work has aimed lower to the ground: the potential ubiquity and necessity of “All-Wood” infill buildings.

Throughout the United States, new mass timber projects currently default to hybrid construction methods

that employ significant amounts of steel, concrete and finishes like gypsum. Due to market assumptions of cost, schedule, code compliance and local fabrication limits, only one All-Wood

building has been built in the western United States: the Mississippi Avenue building by Waechter Architecture.

This body of research aims to break down the percieved barriers to competitive

construction of All-Wood buildings in our region by showcasing lessons learned from our Mississippi project and a range of possible approaches moving forward.

In an All-Wood building, the structure is the finish.

In an All-Wood building, the ceilings, supporting structure and the walls are all exposed mass timber, creating a continuous material experience.

All surfaces can be wood, except perhaps the floor, which depending on programmatic need can be concrete, carpet or other finishes if desired.

Structural Approaches for All-Wood Buildings

We group the various structural components of an All-Wood mass timber into three overtly broad categories: the exterior structure at the envelope of the building, the inner structure throughout the floor plate, and the horizontal structure that supports that floor plate. We find that broadly speaking there are three approaches per category, resulting in a diverse matrix of options that may be considered for particular scales, programs and sites.

Exterior Structure:

Tilt-Up

Exterior Structure:

Platform

Exterior Structure:

None (Cantilever)

Interior Structure:

Columns

Interior Structure:

Walls

Interior Structure:

Cores

Horizontal Structure:

Beams & Girders

Horizontal Structure:

Beamless (Point Load or 2-Way Deck)

Horizontal Structure:

Longspan CLT Beams

MEP Approaches for All-Wood Buildings

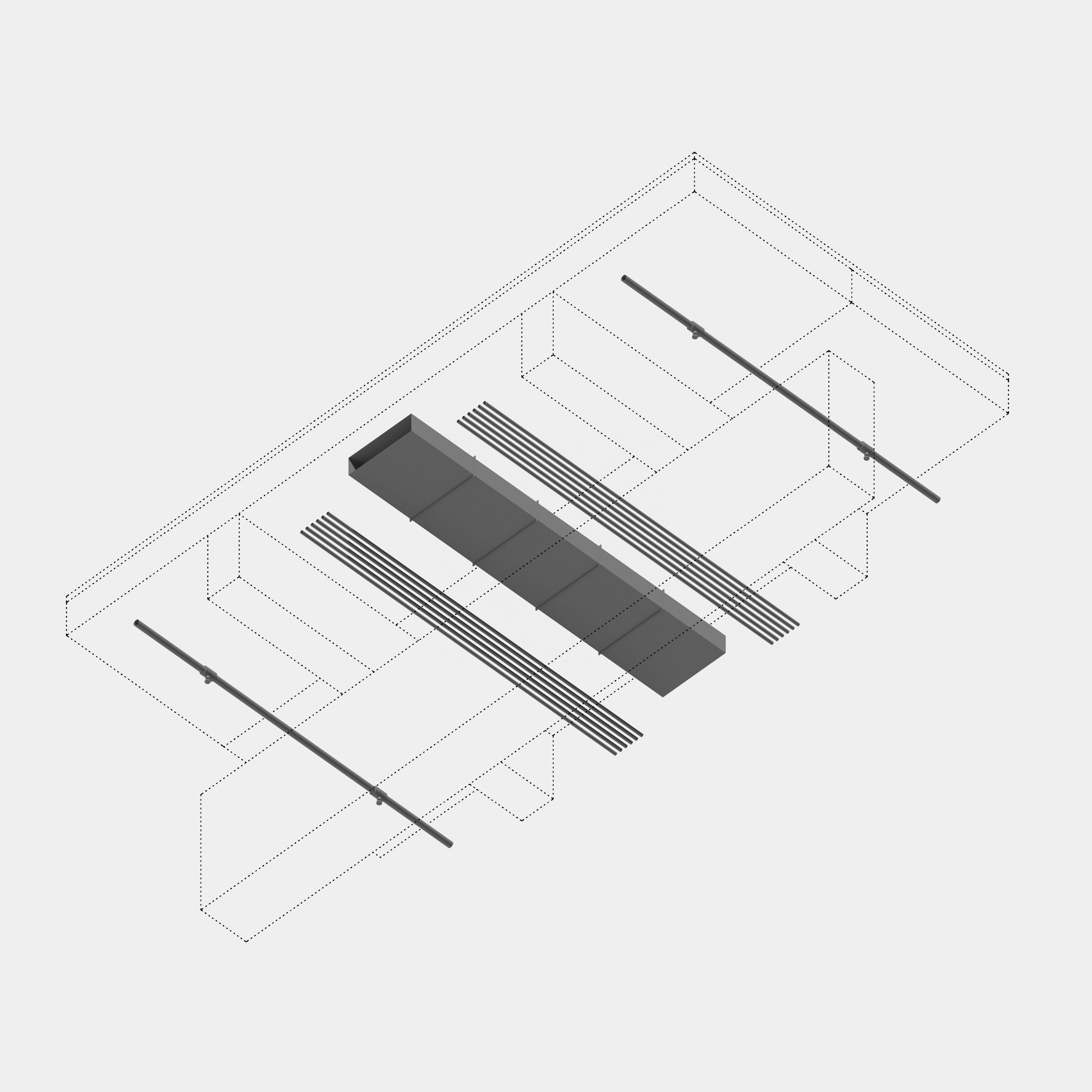

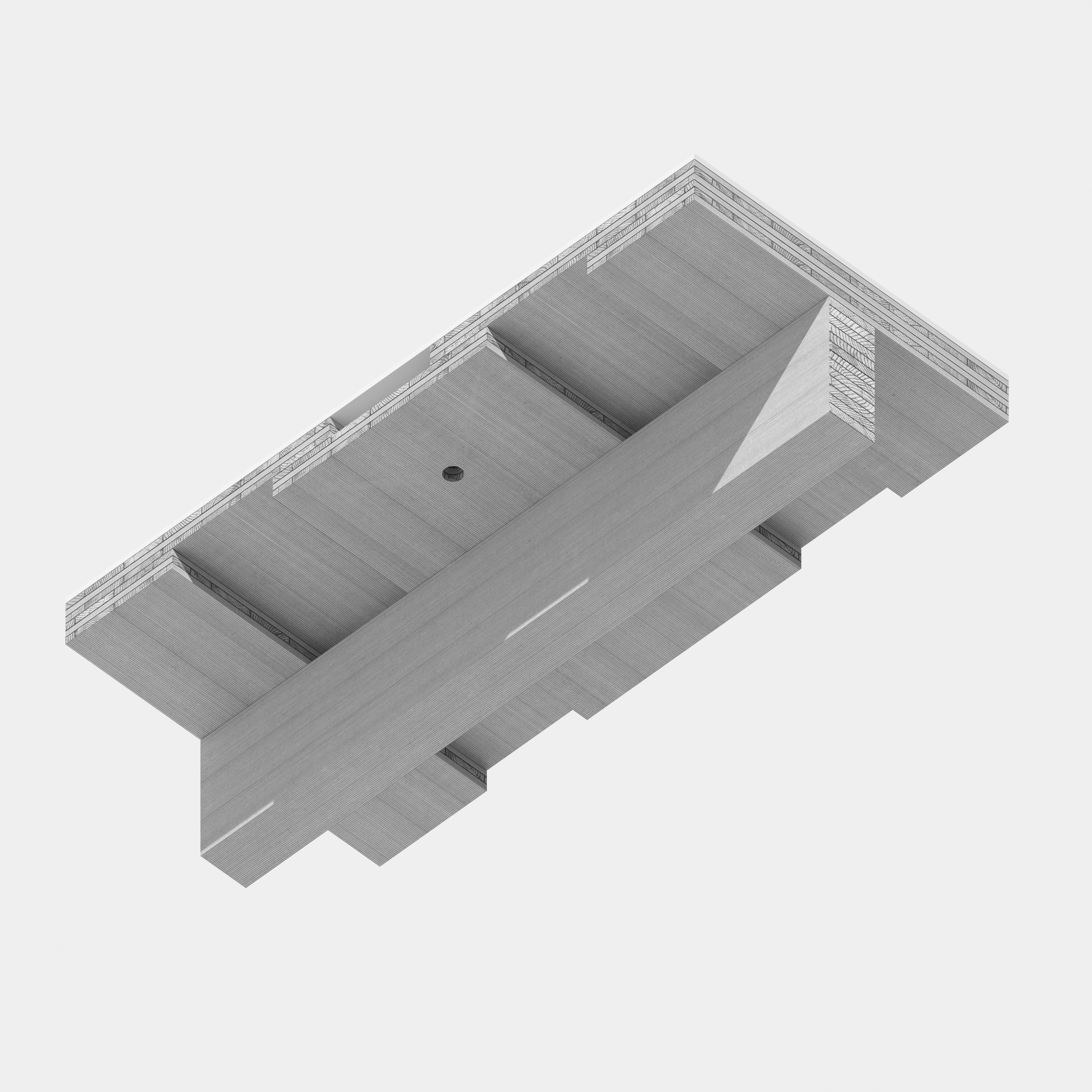

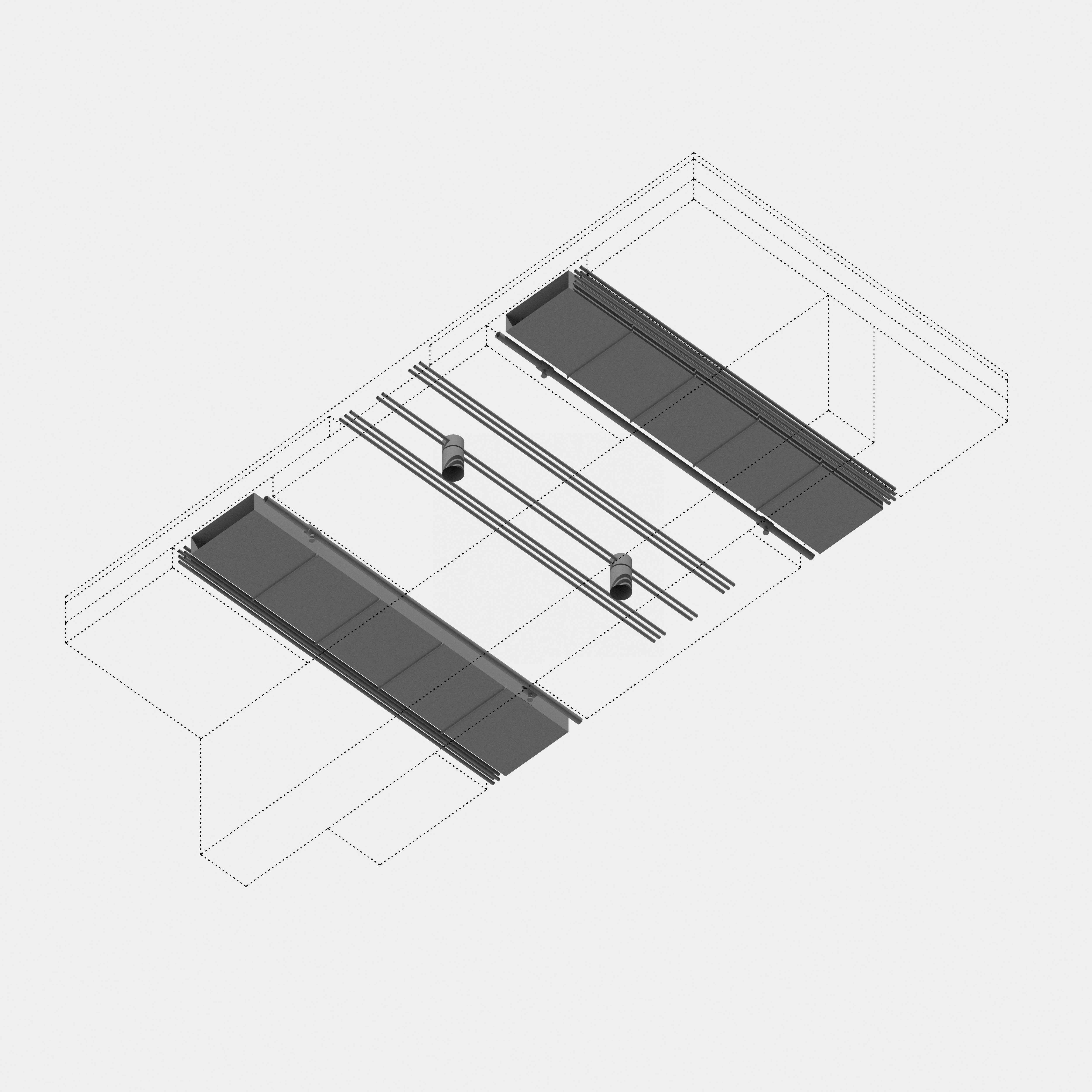

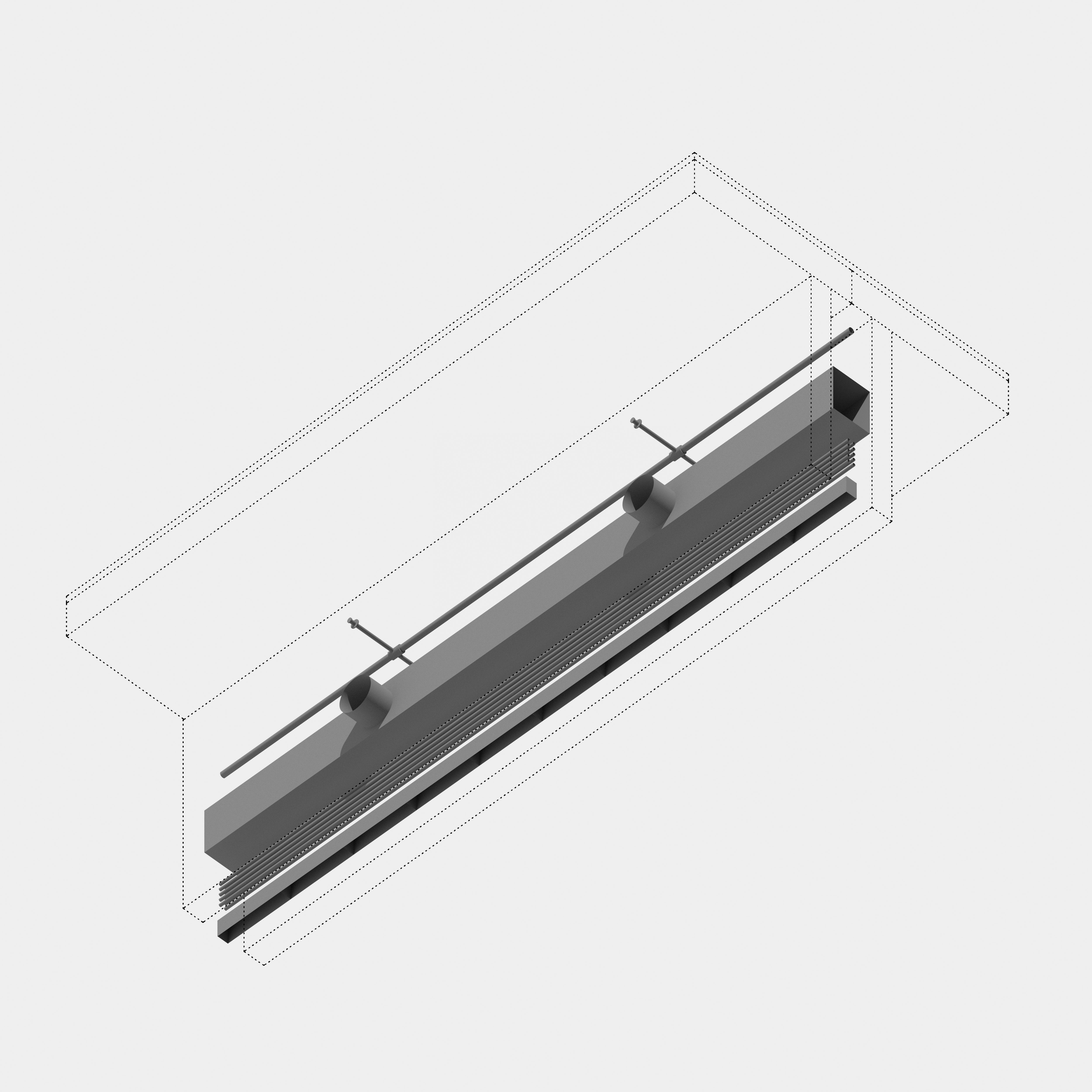

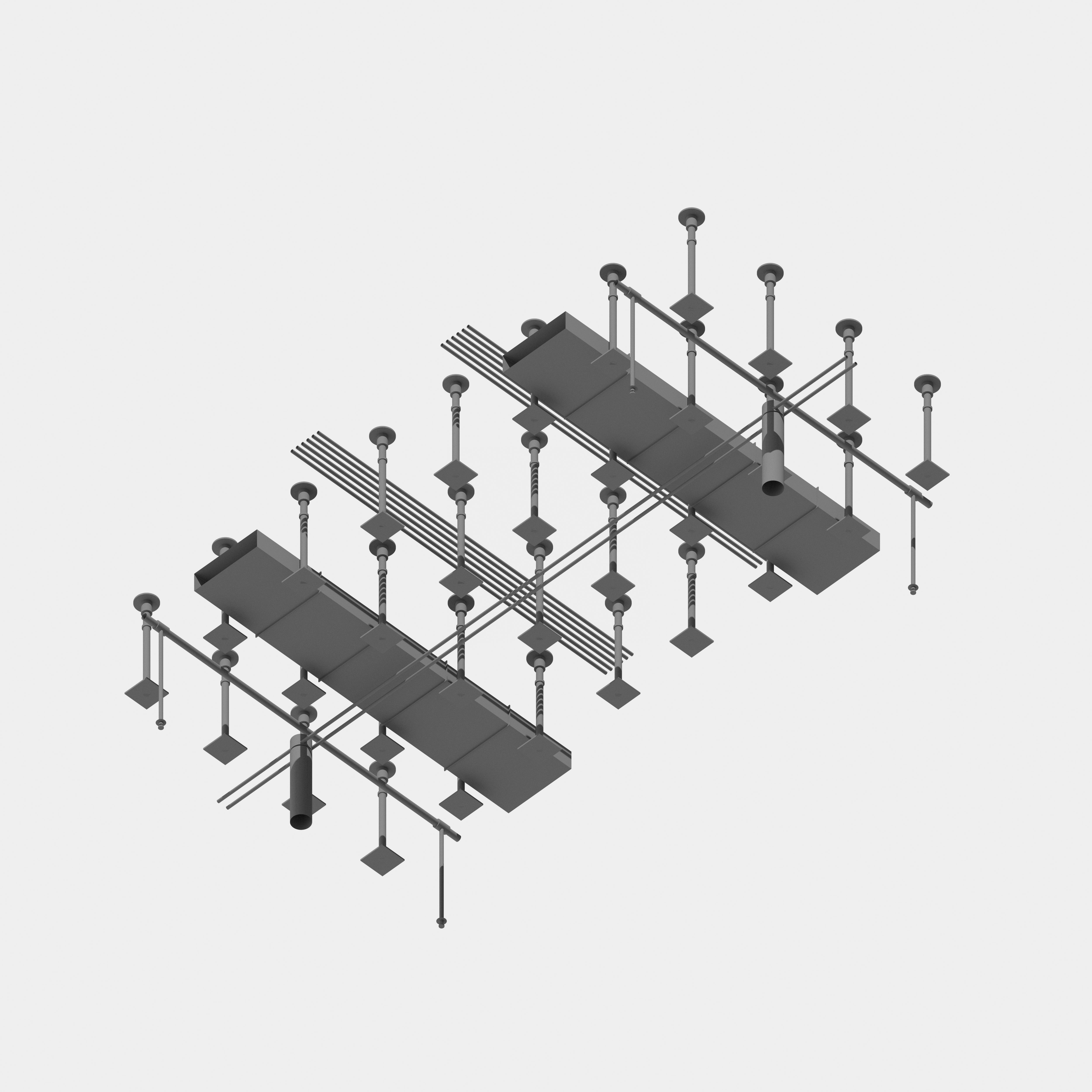

In any mass timber building, one of the most important design decisions and ultimate challenges is how to resolve Mechanical, Electrical and Plumbing requirements. In an All-Wood building in particular, there is no typical wall cavity to hide equipment. Instead, we are identifying a set of five approaches to organizing and sometimes hiding MEP systems altogether in a way that complements our All-Wood structural approaches. The hypothetical details below show the timber elements in one image, and the MEP elements next to it.

Vertical Structural Offset: Timber Elements

Vertical Structural Offset: MEP Elements

Horizontal Structural Offset: Timber Elements

Horizontal Structural Offset: MEP Elements

Structural Cavity: Timber Elements

Structural Cavity: MEP Elements

Integrated Floor: Timber Elements

Integrated Floor: MEP Elements

Raised Floor: Timber Elements

Integrated Floor: MEP Elements

All-Wood Details from Mississippi Ave

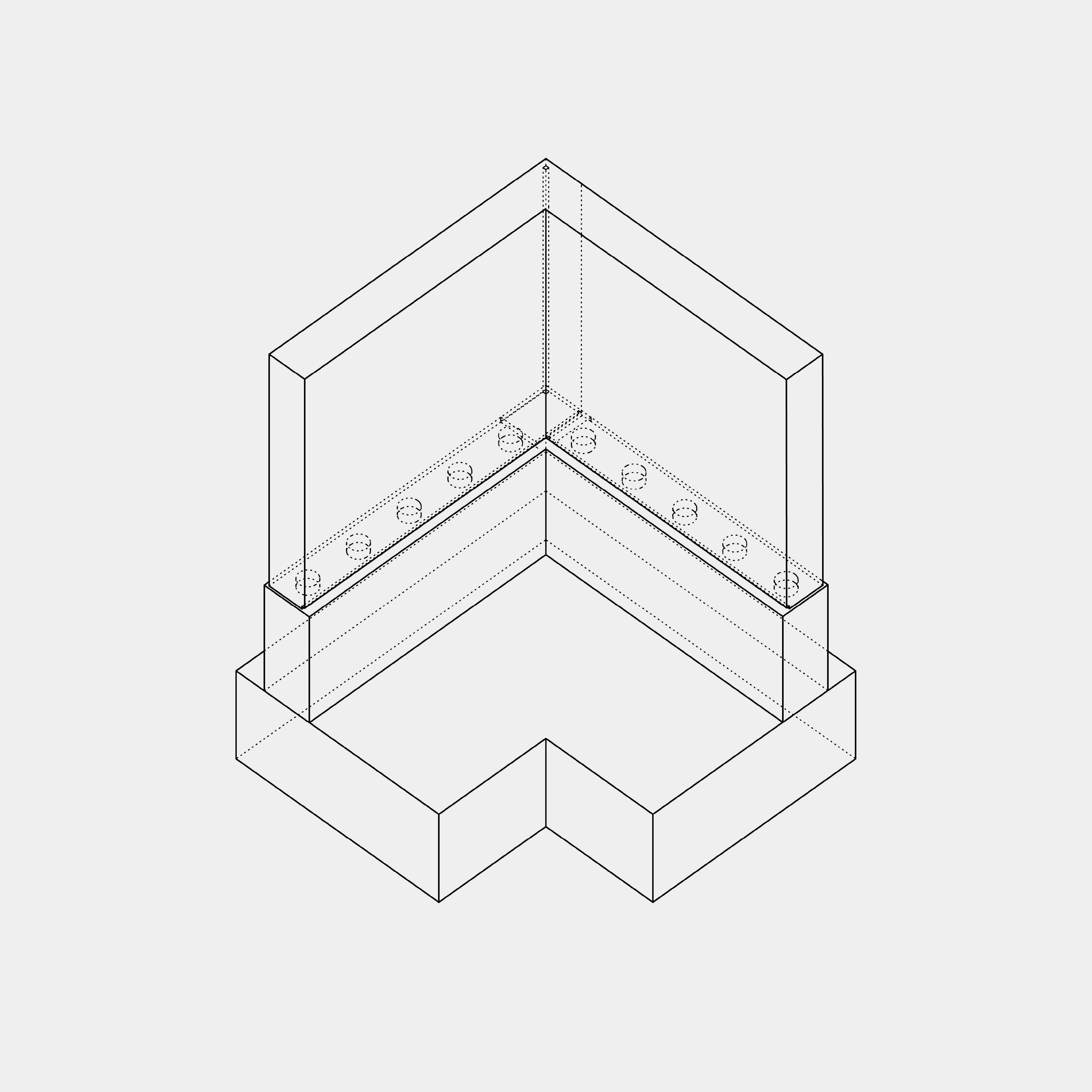

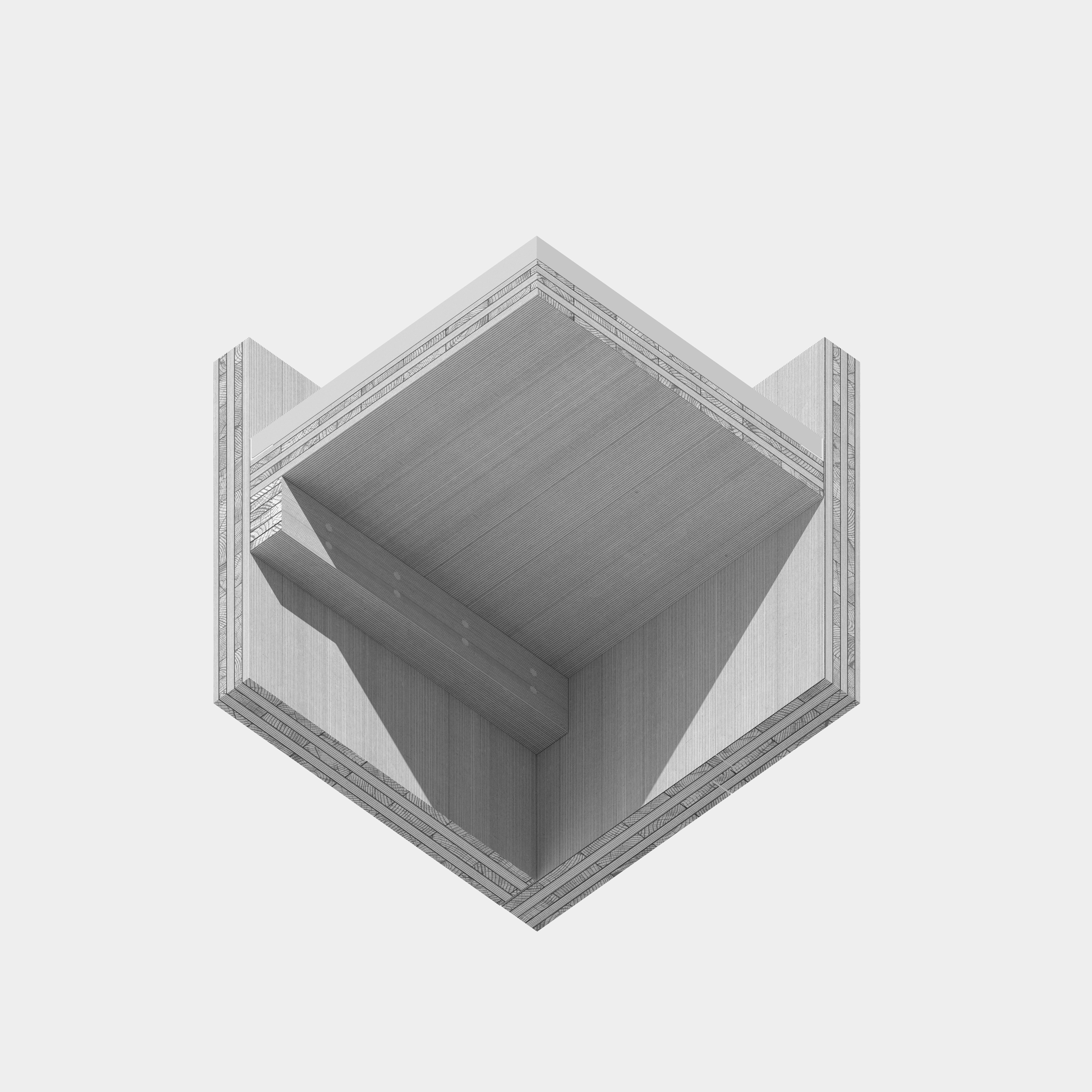

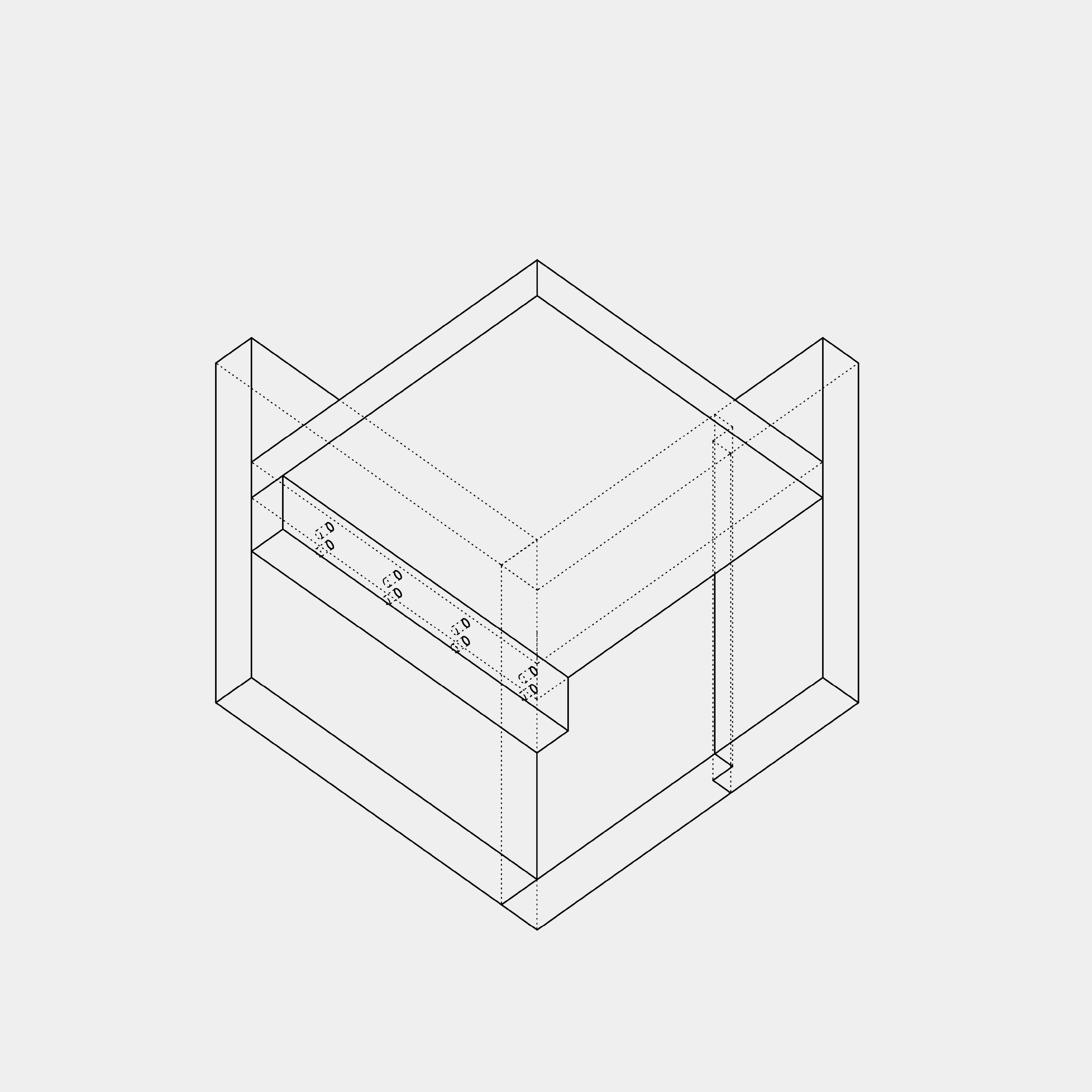

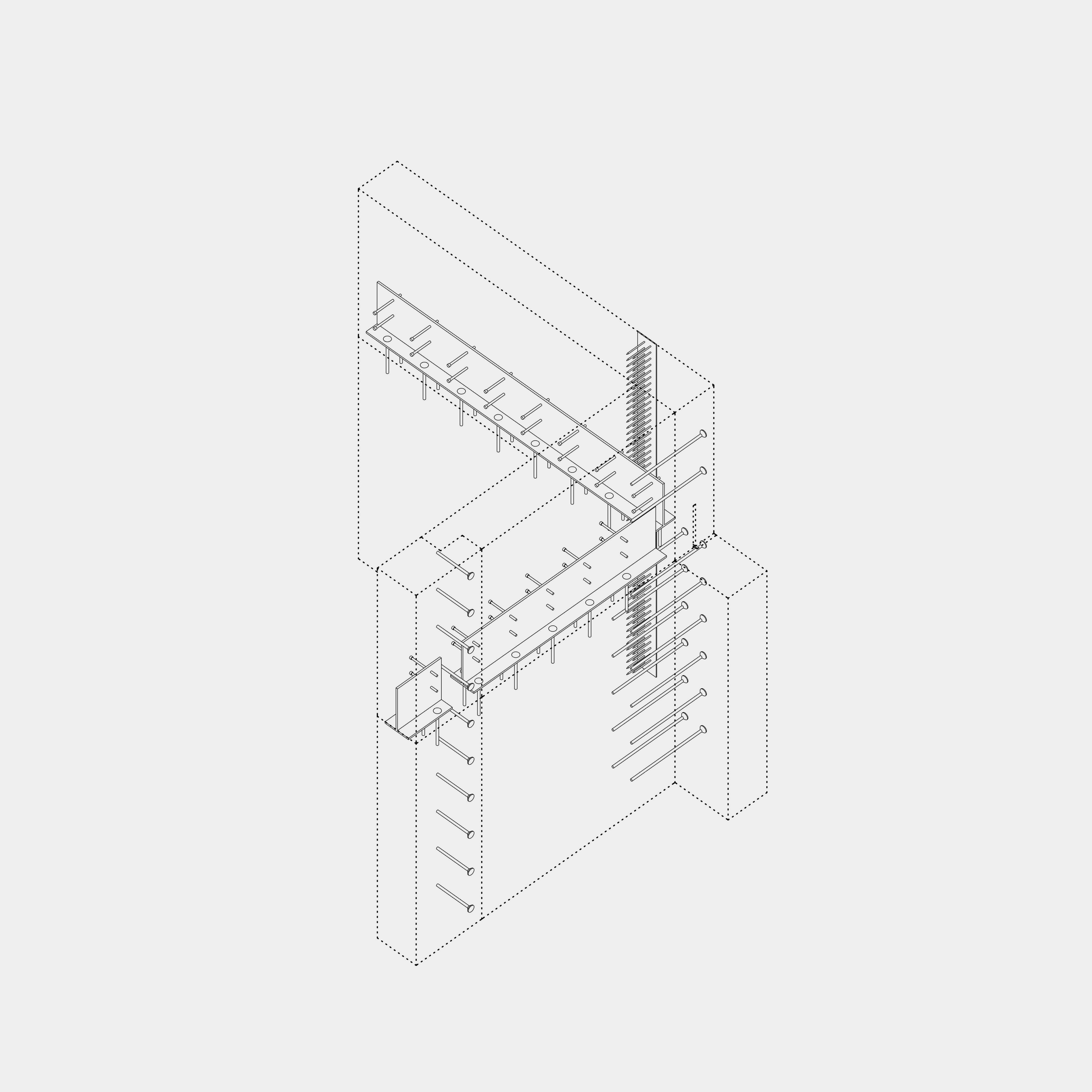

Collecting the key structural moments from our All-Wood Mississippi building, the following details work as a series of triptychs. The first version of each detail expresses the visible assembly, the timber-only assembly second, and third, the major metal fastening patterns. Each one of these details works from a fire code perspective, and for the seismic zone of the Pacific Northwest.

Learn more about this All-Wood building.

Learn more about this All-Wood building.

Beam to Wall Connection: Visible assembly

Beam to Wall Connection : Timber assembly

Beam to Wall Connection : Fastener assembly

Stemwall Bracket Connection: Visible Assembly

Stemwall Bracket Connection: Timber Assembly

Stemwall Bracket Connection: Fastener Assembly

Stemwall Corner Bracket : Visible Assembly

Stemwall Corner Bracket : Timber Assembly

Stemwall Corner Bracket: Fastener Assembly

Ledger: Visible assembly

Ledger: Timber assembly

Ledger: Fastener assembly

Drag Plate Connection: Visible assembly

Drag Plate Connection : Timber assembly

Drag Plate Connection : Fastener assembly

Core Bulkhead Corner: Visible assembly

Core Bulkhead Corner : Timber assembly

Core Bulkhead Corner : Fastener assembly